Products that Perform Under Pressure

Customers in industrial, manufacturing, and processing industries rely on Spuncast’s centrifugal casting expertise to produce products that perform under pressure.

Using detailed routings and ISO 9001-2015 procedures allows us to deliver a defect-free product on time and at a competitive price with virtually no part-to-part variation.

Lifetime Replacement Guarantee: On the rare chance your centrifugal casting products aren’t performing as they should, we will fix it or replace it at any time. Guaranteed.

Precision products at Spuncast

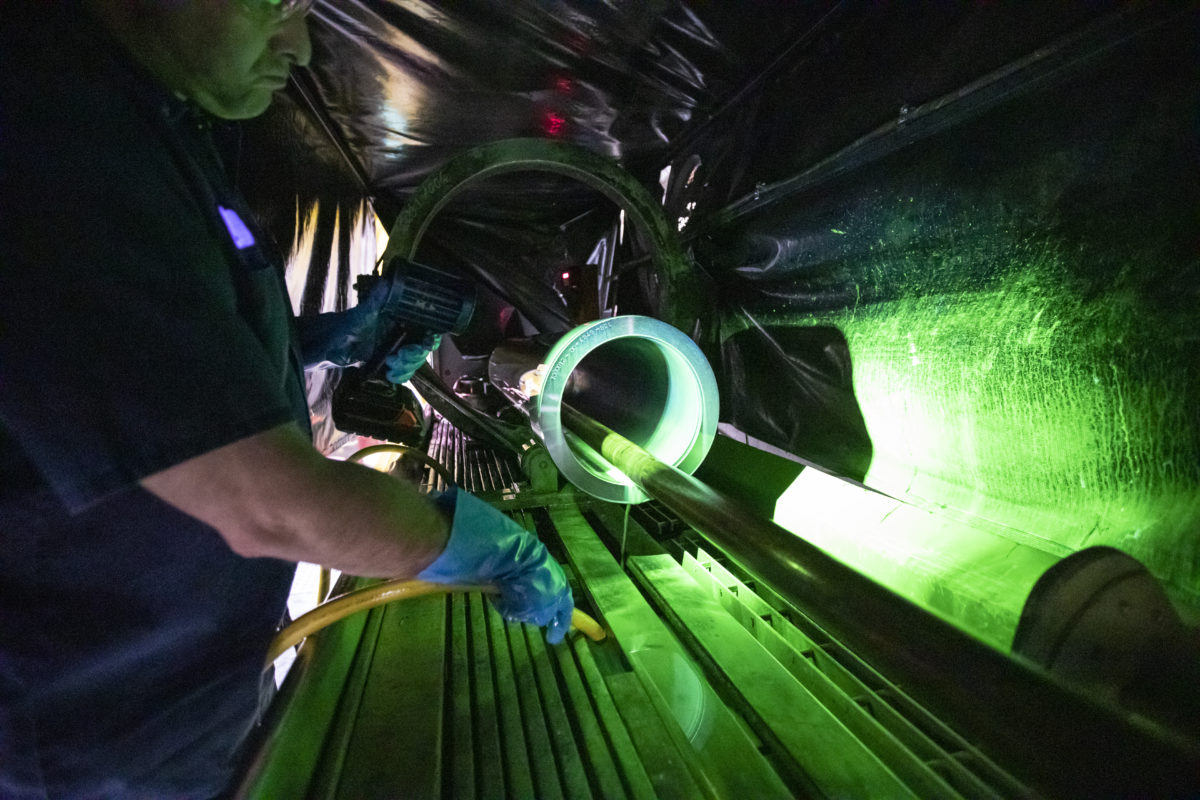

Hydraulic Cylinders

Spuncast’s proprietary High-Velocity Quench System is explicitly designed for tubular parts; it sends a rapid stream of quench fluid through the bore of the casting while simultaneously quenching the outside diameter with high volumes of fluid.

And we can pour up to 11,000-lb. casting and hone up to a 26” ID in surface finishes between 0-16 RMS. We can also hold .003” in the ID for over 20 feet with uniform wall thickness. Our capabilities include but are not limited to:

- Mining truck struts

- Telescoping cylinders

- Scrap metal processing shears

- In-process components

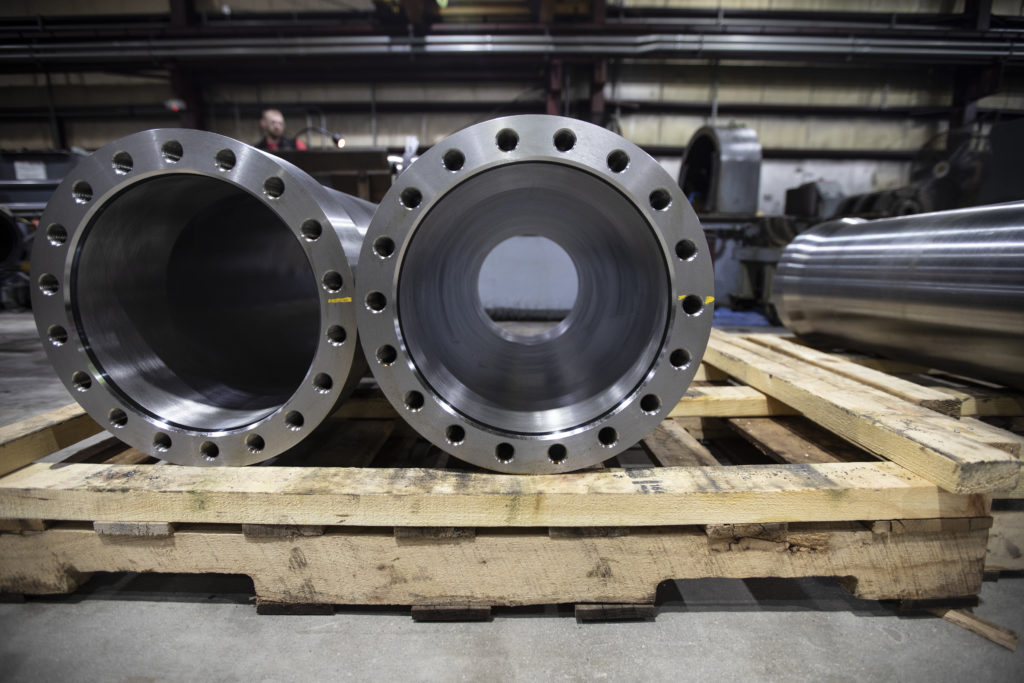

Hydraulic Accumulators

Spuncast has been manufacturing and selling hydraulic accumulator bodies to manufacturers of piston accumulators for over a decade.

It’s experience that means you’ll receive consistently excellent mechanical properties, corrosion resistance, and tight dimensional and surface control on your parts —all with a high degree of repeatability. We produce for many severe service applications, including:

- Navy submarines

- Surface ships

- Energy storage

- Offshore oil actuation systems

- Wind turbines

- And more

Industrial Roll Bodies

Centrifugal castings are an obvious fit for industrial roll bodies because they are formed round, concentric, and free from mid-wall voids. And, they can be further enhanced by surface machining without compromising the integrity of the metal.

Spuncast’s alloy flexibility along with captive heat-treat and machining yield roll bodies poured up to 12,000 pounds and 300 inches in length to produce:

- Continuous casters

- Transfer tables

- Heat treat furnaces

- Float glass mills

- And other roll applications