As the requirement for top-tier machinery intensifies, so does the need for hydraulic cylinders.

To keep up with the evolving demand, the manufacturing techniques behind hydraulic cylinders have gained even greater importance.

In this blog post, we’re diving into the significance of hydraulic cylinders and how centrifugal casting is shaking up the traditional manufacturing methods used to produce them.

Key requirements in hydraulic cylinder manufacturing

Hydraulic cylinders must be designed to hold up to the stresses and conditions of their intended operation, as well as consider any unusual load conditions that may occur.

Both environmental factors and the specific application greatly affect cylinder performance and lifespan, leading to these key considerations:

- Temperature extremes: Degrade components, thicken fluid, reduce efficiency

- Contaminants: Dust, dirt, moisture, etc. wear down parts and cause corrosion

- Vibrations: Put stress on components, leading to fatigue and failure

- Load and duty cycle: Excessive loads, frequent cycling wear components out faster

To address each of these factors, in addition to design, the manufacturing method must be able to create a cylinder that optimizes strength, minimizes wear, and guarantees dimensional accuracy. That requires ensuring the method allows for the following in its processes:

Accurate Material Matching: Custom alloys like duplex, HSLA or PH stainless steels can help combat environmental challenges

Wall Thickness Variations: Wall thickness adjustments along the cylinder body optimize strength and weight distribution based on stress analysis

Grain Structure Refinement: Controlled cooling rates and specific production techniques achieve a finer grain structure, leading to improved mechanical properties

Consistent Quality Assurance: Testing by metallurgists and quality assurance experts ensures material integrity and flaw detection for optimal performance and safety

A paradigm shift in the manufacturing of hydraulic cylinders

Manufacturing hydraulic cylinders has slowly evolved over the years. In the early stages of their production, traditional methods involved processes such as forging, machining, and welding.

While effective, today these methods may incur high costs and have long lead times because they are often followed by extensive secondary treatments to meet the desired specifications.

Luckily, technological advancements in centrifugal casting have brought about a desirable alternative and a paradigm shift in the industry.

Today, the centrifugal casting method offers:

Integration of computer-aided design (CAD) systems:

- CAD systems are seamlessly integrated into the casting process

- Allow for repeatable, consistent design choices

- Optimize the geometry of hydraulic cylinders for improved performance

Precision enhancement through CAD:

- Engineers can fine-tune design parameters with unprecedented accuracy

- Ensure that the centrifugal casting process produces components with exact specifications

Real-time monitoring with control systems and sensors:

- Advancements in control systems and sensors facilitate real-time monitoring

- Enhanced consistency and reliability of the centrifugal casting process

How customization delivers on key design elements

Greg Whitman, Vice President of Sales and Engineering at Spuncast, explains that the centrifugal casting process is particularly well suited for manufacturing hollow tubes like hydraulic cylinders.

“The centrifugal casting process is dynamic – constantly spinning,” he said. “This creates a centrifugal force that pushes the molten metal against the walls of the mold, resulting in a dense, homogeneous cylinder with no internal voids or inclusions.“

In addition to its reliable strength and durability, centrifugal casting offers the following benefits to a hydraulic cylinder design:

- Precise Wall Thickness: This is crucial for hydraulic cylinders, as it ensures optimal pressure distribution and minimizes weight while maintaining strength.

- Reduced Machining Needs: The near-net shape achieved by centrifugal casting often requires minimal machining, saving time and production costs.

- Versatility: Centrifugal casting can handle a wide range of materials making it suitable for diverse applications.

- Production Efficiency: The process is relatively fast and efficient compared to other methods, leading to shorter lead times and cost-savings.

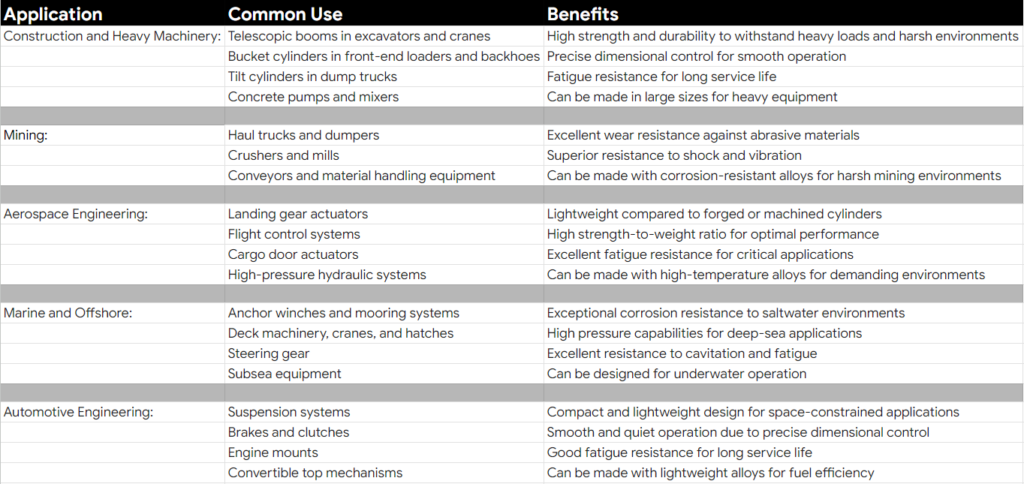

Centrifugal cast hydraulic cylinder use across industries

The robust performance and adaptability of centrifugal cast hydraulic cylinders have cemented their place as a vital component across a diverse range of industries. Their unique properties translate into reliable benefits for specific applications.

Is a centrifugal cast hydraulic cylinder right for your design?

While centrifugal casting is a strong choice for many applications, it’s not always the perfect solution. Here are some considerations:

- Mold Cost: The initial investment in molds can be higher compared to other methods.

- Limited Geometries: Complex shapes and features may require additional machining or casting techniques.

- Material Limitations: Certain materials might not be suitable for centrifugal casting due to their viscosity or solidification characteristics.

For applications demanding high performance and long service life, the advantages of centrifugal casting – from dimensional accuracy to reduced material waste – make it a truly innovative and viable option.

However, it’s important to carefully consider the specific requirements of the application and the limitations of the process before making a decision.