Manufacturers using LTL (less-than-truckload) carriers to ship their steel tube products are grappling with a cascade of factors leading to shipping cost increases.

Even though 2023 diesel costs are expected to decrease to an average of $4.23/gal, LTL carrier rates remain on an upward trend. So, despite the current market conditions that favor renegotiating, most manufacturers find relief not guaranteed.

Below, we dive into why LTL carrier prices continue to rise and examine what you can do to control your custom tubing shipping costs. But first, a video on the subject:

Why are LTL carrier rates still rising?

Because the top 25 LTL carriers control more than 80% of LTL capacity, carriers have been able to use market concentration to their advantage in terms of pricing.

An article for Supply Chain Management Review reported that at the beginning of the year, most LTL carriers stood firm on their general rate increases, which took effect in January.

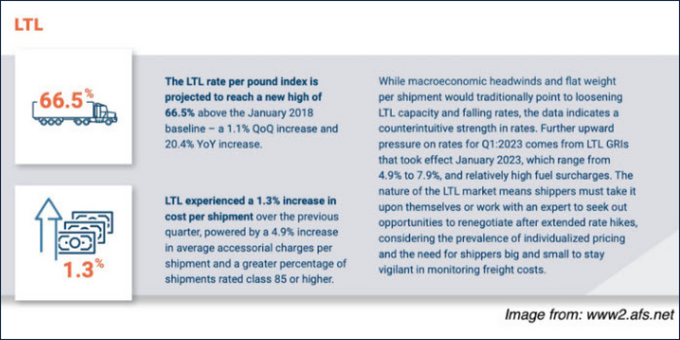

An article in Business Wire backs up that claim with numbers from the most recent Cowen/AFS Freight Index, proving LTL rates are climbing toward a new high.

The report shows the LTL rate per pound index is projected to reach 66.5% above the January 2018 baseline, with a 1.1% increase quarter-over-quarter and a 20.4% increase year-over-year.

It’s a contrary result considering fuel surcharges are cooling. According to SupplyChainBrain, LTL carriers have more fixed overhead costs than other carrier options and credit the rise to influences like:

Operational Costs: Various expenses, such as labor, maintenance, insurance, equipment, and overhead, all contribute to the overall rates. If any of these costs increase, it can result in higher carrier rates.

Demand and Capacity: LTL carriers also consider supply and demand dynamics when setting their rates. If there is a higher demand for shipping services, carriers may increase their rates, irrespective of diesel prices. Additionally, carriers have more leverage to charge higher rates if there is a capacity shortage in the market.

Market Conditions: Economic conditions, market competition, and industry trends can also impact carrier rates. Even if diesel prices are decreasing, carriers may adjust their rates based on the overall market conditions, such as increased operating costs, changes in customer demand, or competitive factors.

Tariffs and Regulations: Changes in government regulations, such as new safety or environmental requirements, can increase carriers’ costs. These additional expenses may outweigh the benefits of lower diesel prices, resulting in higher carrier rates.

A continuing problem for small to mid-size manufacturers

The situation is particularly challenging for small to mid-size manufacturers who lack sufficient freight volume to fill an entire truckload. They find themselves in the position of needing to stretch their shipping budgets to the maximum.

However, they face distinct disadvantages without comprehensive industry insights and the capability to ship in large quantities.

“The nature of the LTL market means shippers must enlist the help of an advocate and proactively seek out those opportunities, considering the prevalence of individualized pricing and the need for shippers big and small to stay vigilant in monitoring freight costs,” says Kevin Day, president, LTL, AFS Logistics.

Viable, cost-saving solutions are possible

Despite the grim statistics, there are practical solutions that can help alleviate these pressures and streamline the shipping process.

1. Consolidating shipments

This approach is especially crucial when transporting awkward shapes, like custom-designed tubing, that don’t always fit neatly together. By comparing carrier rates, consolidating shipments, and optimizing schedules, you can significantly enhance the ease and affordability of shipping products of almost any size.

2. Efficient schedule management

Through vigilant monitoring of prevailing carrier rates and understanding the elements required to secure the best prices, cost-effective options for your shipping needs can be found. It requires the capacity to consolidate and schedule orders to minimize inconveniences and avoid unnecessary costs.

3. Proximity to transportation

Finding a transport solution closer to shipping lanes, ports, and rail systems offers yet another avenue for reducing costs. Centralizing where your products ship from will reduce mileage, opening up more affordable transport options.

Minimizing the impact of LTL carrier price increases

At Spuncast, our in-house shipping team has been helping customers navigate the challenges of the LTL carrier market for years. We offer a Foundry-to-Factory shipping solution that gives a practical choice for transporting custom tube products directly from our business.

- Our midwestern location, which is in proximity to major shipping lanes, ports, and rail systems, minimizes mileage and unlocks more affordable transport options.

- By comparing the rates among our vast network of trusted carriers, our team is able to secure the best possible pricing for those customers shipping through Spuncast.

- Our ability to consolidate shipments and optimize schedules ensures minimal inconvenience and helps avoid unnecessary costs.

Spuncast customer, Weir Minerals, is an excellent example of one of our customers who has significantly benefited from our optimized shipping routes and coordinated orders.

“They decided to give Spuncast shipping a try several years ago,” said Brett Collins, Spuncast Shipping Coordinator. “Now, since switching to shipping with Spuncast, the company reports a 25% reduction in freight costs.”

Learn more about our Foundry-to-Factory shipping and how we can lower the cost of shipping your custom designed stainless steel tubes.